Electric Supercar Contract Work

JUSTIN WANG

MECHANICAL ENGINEER

Work Experience

Seres / SF Motors - (2018 – 2024)

Electric Drive Units – Designed motor housings, lubrication, and cooling systems from ideation to commercialization.

Dynamometers – Tested, debugged, and repaired electric motors from prototype to production design.

Project Management – Aligned with other subsystems and negotiate with external customers and international vendors.

Resource Management – Scheduled and supported testing sessions for mechanical, electrical, and software teams.

Senior Mechanical Engineer (2019 – 2024)

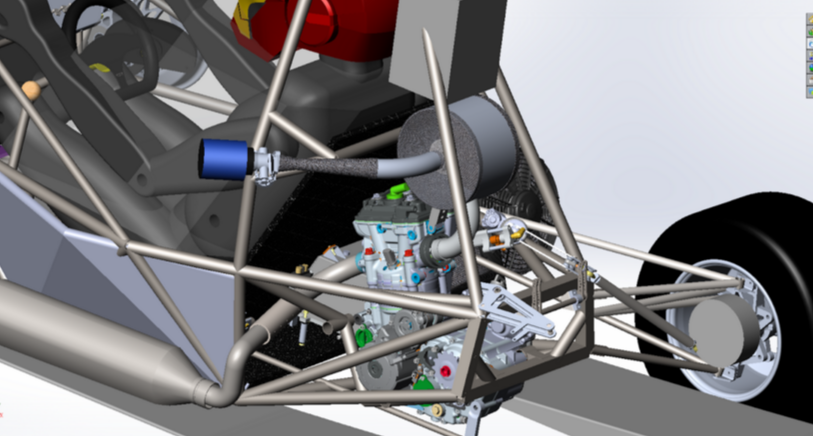

Designed housings and components for electric drivetrain motors, gears, and batteries in CATIA V5, using solid and surface modeling, to be mass-manufactured with high-pressure die casting and lost foam casting methods.

Accomplished significant cost reductions in high-volume production by enhancing assembly and part design, optimizing manufacturing processes, and collaborating with international contract manufacturers.

Reduced assembly part count, standardized hardware, implemented innovative sealing techniques, and selected alternative off-the-shelf components.

Achieved successful delivery and provided ongoing support for our drivetrain package, which has been utilized in tens of thousands of SERES SF5 and AITO (Huawei) M5 cars on the road.

Collaborated with simulation engineers to facilitate their work by providing pre-processing models and conducting post-processing tasks such as optimization, correlation, and validation.

Utilized Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) within the ANSYS suite to conduct basic studies on stress, deflection, resonance, thermal, and flow.

Provided training and mentorship to interns, junior engineers, and technicians, fostering a positive and collaborative company culture.

Senior Test Engineer (2018 – 2019)

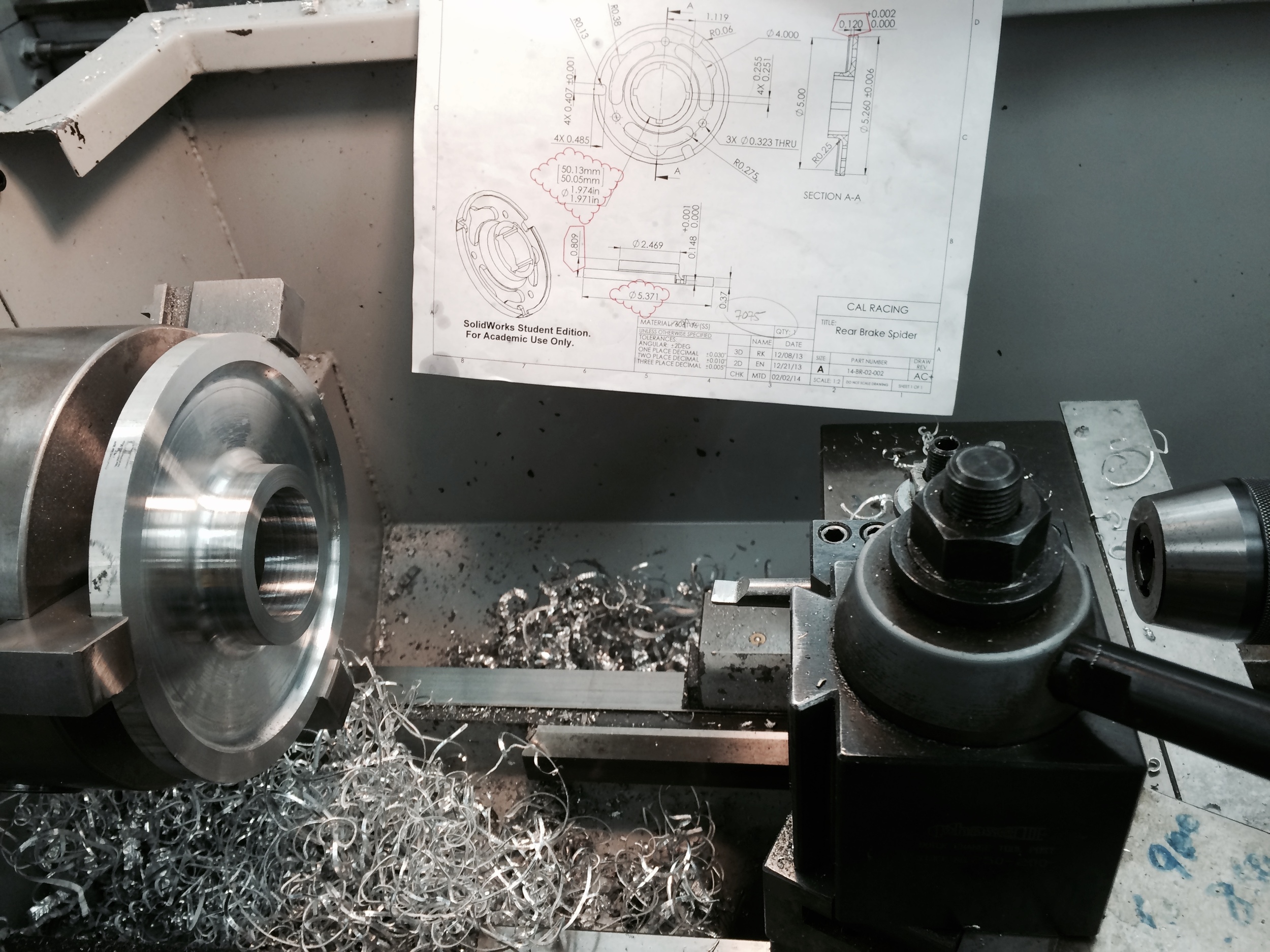

Developed and implemented Coordinate Measuring Machine (CMM) programs to automate the measurement and generation of detailed Geometric Dimensioning and Tolerancing (GD&T) reports for First Article Inspection (FAI) of electric drivetrain components.

Identified critical errors in position, runout, cylindricity, perpendicularity, flatness, and other GD&T parameters, providing proactive process feedback to volume suppliers to mitigate existing and potential manufacturing issues.

Led cross-functional collaboration by providing feedback to designers, guiding them to tighten critical tolerances and eliminate unnecessary specifications, resulting in improved performance, reliability, and reduced volume manufacturing costs.

Significantly shortened the time between design phase release by several months and saved tens of thousands of dollars by reducing outsourcing expenses.

Prototype Vehicle Engineer (jan 2018 – april 2018)

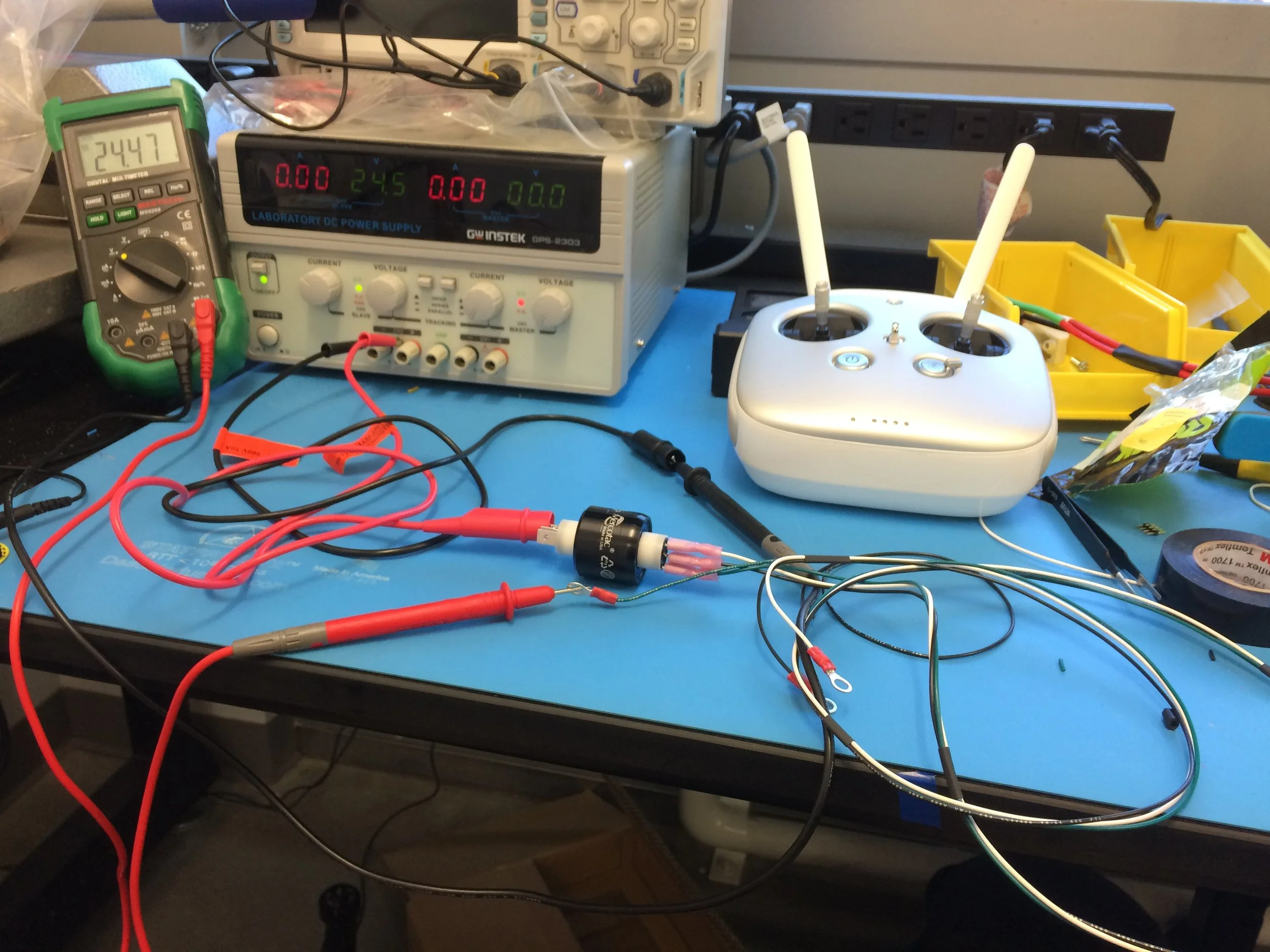

Fabricated electrical wiring harnesses and mechanical hardware mounts, successfully delivering a development "mule" vehicle within a three-month timeframe.

Diagnosed, debugged, and determined root causes of complex mechanical, electrical, and software challenges, ranging from vehicle system-wide problems to individual component-level intricacies.

Provided a robust testing platform for evaluating mechanical systems, power electronics, and control algorithms, resulting in a reduction of time and costs associated with early-stage product development.

Click below to see some Car and Garage related YouTube videos I’ve made.

Other Related Qualifications

Engineering Background – Comfortable reading and learning technical specifications, requirements, and capabilities of products.

Digital Content Production – YouTube experience, website and domain creation (Shopify, Etsy, Squarespace, Hover).

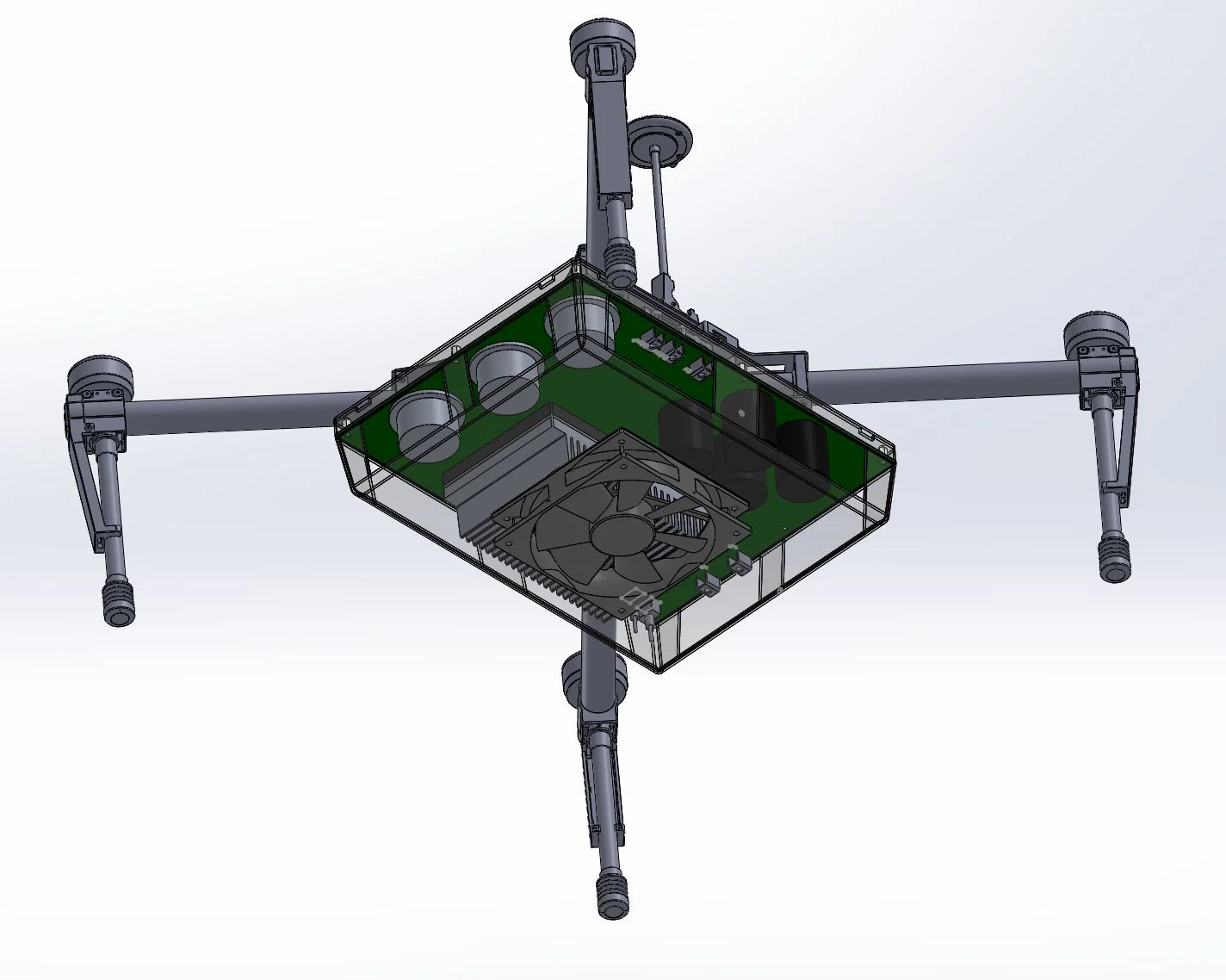

Automotive, Organization, and Tech Passion – Curiosity and interests aligned with Electric Supercar.

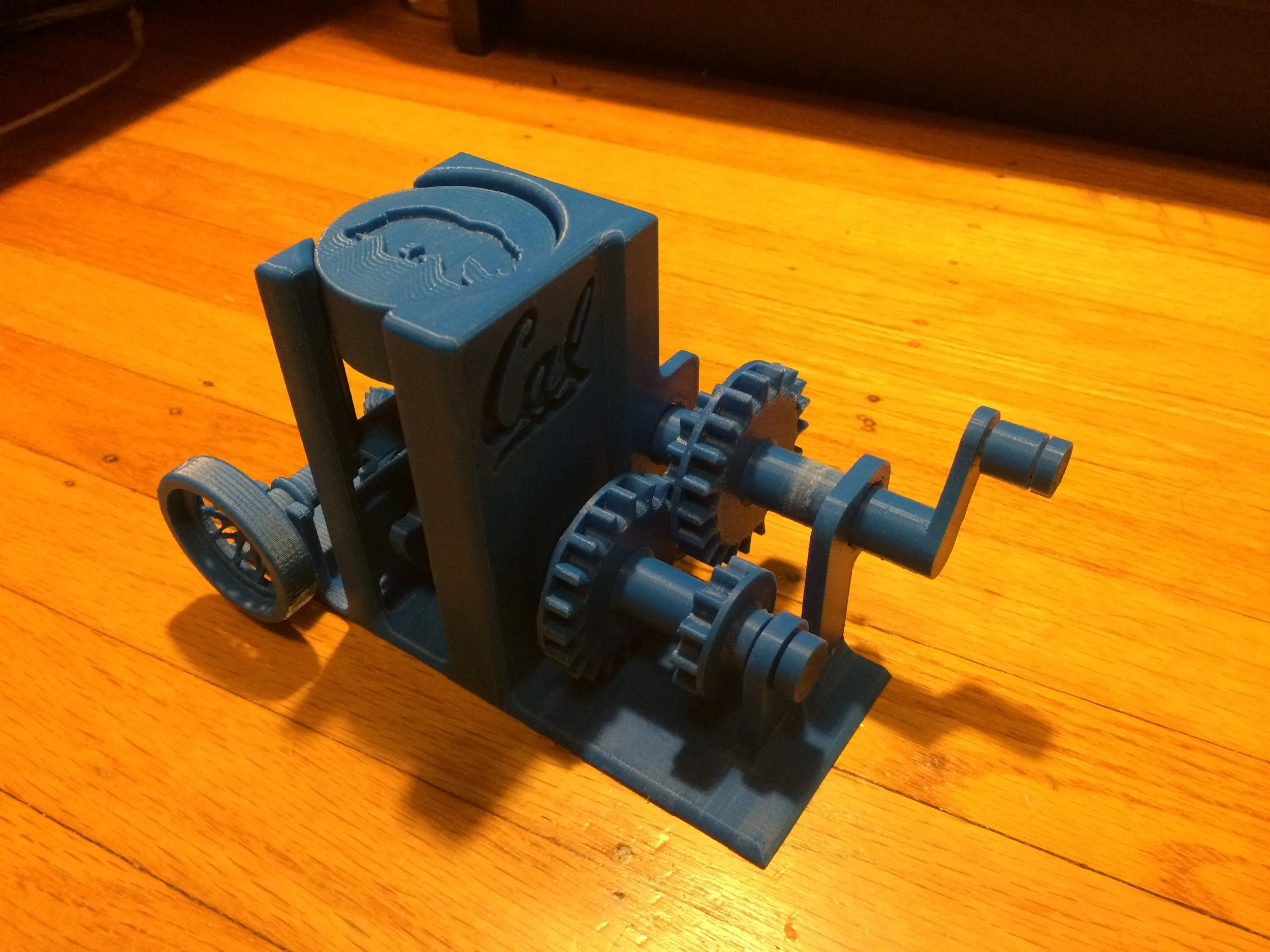

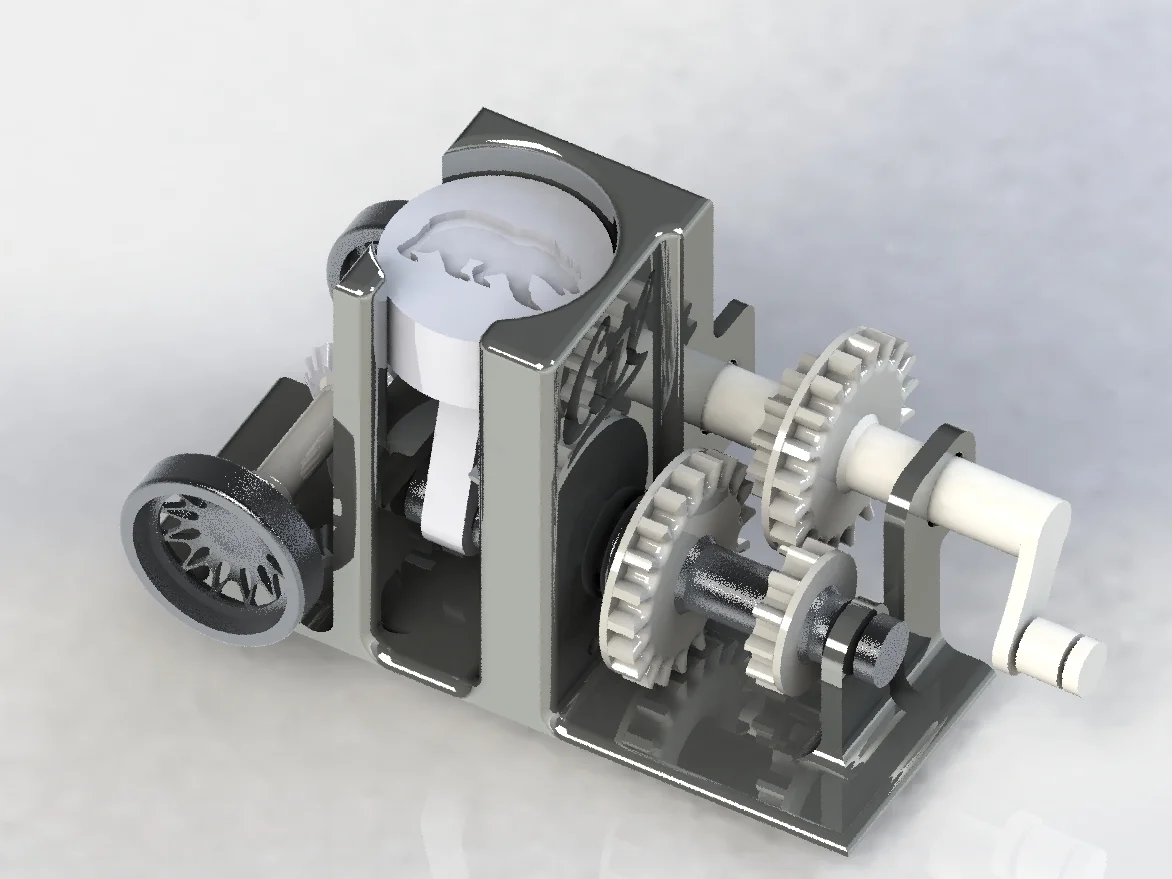

Building and manufacturing – Good at turning a wrench and prototype fabrication.